Flettner Fl 265

© Randy Asplund

I'm a

historical aviation buff. I especially like the early stuff, the more

historically innovative, and... the wacky. Ever since I was a kid I

have enjoyed building models of them, and I promised myself that after

I finished the last batch of painting commissions I would take down one

of the many boxes of kits laying around, and build it.

Once

upon a time, I bought a model of one of the earliest operational

helicopters, the Flettner 265. The real one is just over 20 feet from

nose to tail, and the 1/72 scale model is about 3-1/2 inches. The kit

didn't look too complicated, so I figured it would go pretty fast....

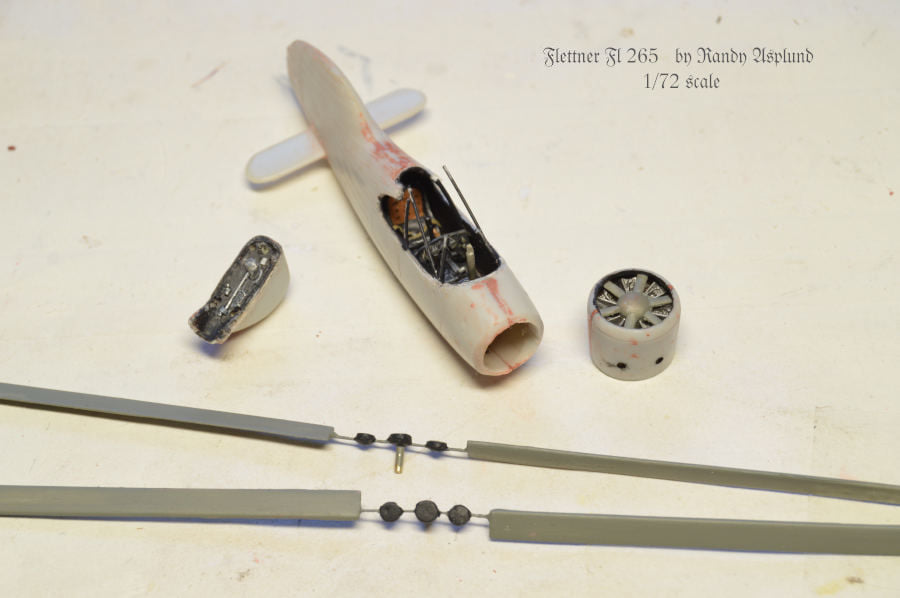

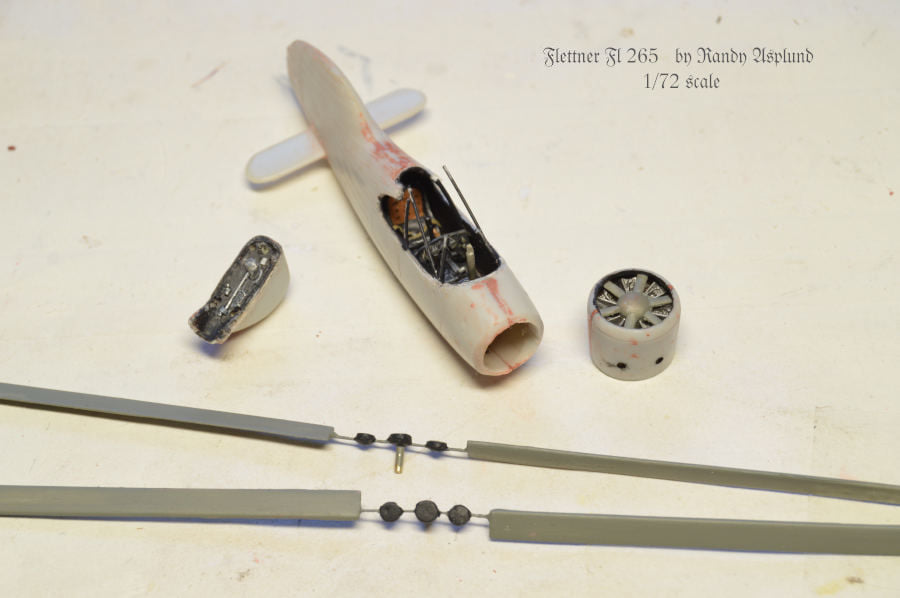

Uh, no. There were “issues.” The kit, by Special Hobby

(from the Czech Republic) is a combination of good attempts, but

lousy/lazy follow-through. There were several resin parts, which give

good detail, but the seat wasn't fully cast, and the canopy had

yellowed. It was that really thin vacu-formed kind of canopy, and was

not well defined, so cutting it out was guesswork. But being yellow, I

junked it anyway. One thing I hate about these kinds of kits is they

can' be bothered to provide all of the parts, and they make you

manufacture some. You better know what you are doing.

Making

some rods by stretching some plastic sprue over a candle is no biggie,

but the instructions give the wrong length. The maker couldn't be

bothered to provide locator pins on the parts, and some parts just

didn't fit. For example, the engine is too big for the cowling! And

they provide resin exhaust pipes that you are supposed to add to the

outside of the cowling... but the box cover and the existing photos

from my research clearly show they don't exist. The extant photo also

shows the decal of the Flettner serial number should be different, and

on the rudder, not the vertical stabilizer. Oh well, that's why you do

research.

Whoops!

I broke a part! There are a lot of weak, flimsy parts in this kit. The

worst are the rotors. The rods that hold the blades are SKINNY as hell,

and guaranteed to have a short life expectancy. I plan to eventually

move to Sweden, so they would never survive packing. But it wasn't the

rotor that broke! It was the fuselage above the door, which connects

the gearbox above the canopy to the rest of the body. It broke right at

the little window on both sides. But that's fine because it allowed me

to do something better.

I

decided to make my rotors tough and removable. So I cut off the struts

that go to the blades, saving the control lever covers (little disks)

and replaced them with spring steel wire. I channeled out the underside

of the rotors and disks with a saw, epoxied them in, and covered it

with Bondo. I epoxied brass rod to the center to make the axles. These

would bayonet down into the top of the gear box and fitting snugly so

they can rotate, would be able to give rather than break if bumped, and

can be pulled out for packing. Oh, wait. These are supposed to emerge

from a large opening in the top! The maker didn't bother to mold that

detail. So I had to carve the plastic thin there to make a shallow

recess. Underneath I added drilled-out sprue to receive the axles. This

was heavily epoxied for strength.

After

the cockpit had been built and painted (much easier to assemble with

the gearbox OFF!), I cut a piece of brass rod to serve as the drive

shaft (goes up from a box on the cockpit floor to connect with the gear

box above the canopy). I carefully cut it to exactly the length

required, plus enough to file out a prong on each end that would

bayonet into drilled holes. Great, except that the length given in the

instructions was wrong. I had to remake it. But when finished and

epoxied together, this piece made a really sturdy upper structure above

the canopy.

The

canopy was a challenge since it was intended to fit an opening, but

there was no recess to prevent it from pressing through all the way

when you glue it in. I had to create a raised rim inside the window

openings, leaving just enough space for the clear pieces. Like putting

glass and a photo into a frame.When it dried, I put thin masking tape

over the window and marked the size and shape for the clear pieces.

This tape went onto some thin commercial packaging plastic, and was

carefully cut out. Fortunately the only pieces needing to bend were

easy to curve. I trimmed the canopy with 24 lb paper that had been

coated with clear acrylic medium before cutting.

There

are little bulges on the superstructure that had to be made, the box

art has some wrong details, like a grill that doesn't exist and the

door handle in the wrong place. The struts should NOT be RLM 66

(black-gray), they should be RLM 2 (medium yellowish gray). Colors were

mixed to conform to the color chip insert in Michael Ullmann's book

Luftwaffe Colors. I NEVER mix my colors with white to lighten them for

“atmospheric perspective.” Why? Because it is false color.

But also, that approach presumes a standard viewing distance, and if

you are at a different distance it doesn't work. I'm trying to make

historical miniatures. I'll save “atmospheric perspective”

for paintings, where it belongs.

The

tail wheel was all wrong and needed to have the struts cut off and

rebuilt. And they were too lazy to mold the opening, so they give

measurements (wrong again) for where to put it and how long it should

be cut. You get to invent something to mount the tail wheel struts

onto. I also had to bevel the nose right before it goes under the

engine cowling. That meant building brackets inside to mount the engine

cowling.

This

helicopter has its engine in front, like an airplane. And it looks like

it has a little toy propeller buried inside. That's actually a cooling

fan, but could Special Hobby be bothered to make the fan blades as fan

blades? Nah. They are just symmetrical hump sectioned with a flat rear.

One

thing I'll say that I liked about this kit are the decals. They are on

a very sturdy but thin film. They laid down perfectly and didn't tear

when being positioned. Going over a gloss lacquer and then a SPRAYED

dull coat on top of the decal, you don't see the film at all.

You

might want to know what's up with how the rotors are arranged. This

bird has a pair of counter-rotating rotors. They sit at shallow off-set

angles, so they look pretty wonky when stationary, but it is just the

way it is designed.

There

were only about five Fl 265s put into service as deck helicopters,

being used in 1939-40 on German Cruisers. They could lift small cargo

or rescue downed pilots. There is even a color movie clip of one

demonstrating and air-rescue of a dummy pilot from a raft. By the

Korean war helicopters were routinely doing these duties.